The departments affiliated with the member of the Management Committee for Maintenance and Refinery Operations consist of the following departments:

Monitoring the operational process in the fields

Operations management was followed by a number of oil fields and ports producing oil, such as Al-Sarir, Masla, Al-Nafoura, Majid, Al-Bayda, and Hamada fields. The administration carries out the process of technical, operational and production activity from the oil fields to the pumping process to the export ports, which are Hariga Port, Zawiya Port, Ras Lanuf Port, and Zueitina Port. Most of the fields consist of sub-complexes and main complexes, which contain all the main equipment from manifolds, salt separators, production separators, tanks, sub-pumps, main pumps, equipment attached to the gas system, gas processing plant, gas incinerators, gas compressors, gas network, etc. Auxiliary equipment in the production process.

The organizational structure of the department consists of field managers, coordinators, department heads, supervisors, foremen, and operators, and their primary function is to monitor, operate, and produce 24 hours a day to maintain the progress of the operational process in these fields, in addition to preparing technical reports, production, pumping, inventory, well testing, and other important daily, weekly, and monthly reports. Quarterly, semi-annual and annual technical reports, following up on purchase requests and the budget, coordinating between other departments and developing project proposals for maintenance and renewal of machines and production equipment, etc.

The number of maintenance department users at the Arabian Gulf Oil Company is approximately (1,167 users), distributed across the company’s websites according to the following ratios:

- Administration (Benghazi) (2%)

- Harika Marsa (3.2)

- Sarir field (22%)

- Masala field (18.3)

- Nafoura field (21%)

- Al Bayda field (9%)

- Hamada field (15%)

Management goals:

Maintenance is a group of technical and administrative activities that aim to preserve equipment and machinery, or return them to their normal operating condition to perform their required purpose with the least time and cost. Many types of maintenance are applied within the administration, such as: preventive maintenance, periodic maintenance, and comprehensive maintenance (Umrah). Implementing administrative and technical procedures based on analyzing the cost of malfunctions, the cost of maintenance, and the cost of equipment downtime. With thoughtful plans, trained technical workers, estimation of spare parts needs, and monitoring of the implementation of these plans.

Maintenance supervisors in the fields and Marsa Al-Harika, Tobruk, prepare, implement and follow up on various daily, programmed and emergency maintenance works, prepare requests to purchase the necessary spare parts, workshop supplies and necessary equipment, and follow up on the stock of spare parts in coordination with the supply management departments at the sites according to the established plans. These controls have departments in various specializations of mechanical and electrical maintenance, precision machinery, control, and power generators.

Refining activities

Refining activity is considered one of the most important activities in the oil industries, as it was entirely affiliated and managed by the National Oil Corporation. This activity was assigned to the Arabian Gulf Oil Company, which represented the Tobruk and Sarir refineries in 1991.

First: Monitoring the Tobruk Refinery:

The refining capacity of the Tobruk refinery is 20 thousand barrels per day of Sarir crude. The refinery produces liquefied petroleum gas – untreated naphtha – kerosene – diesel fuel – heavy fuel oil, and the products are pumped through the pipeline to the Brega Oil Marketing Company warehouse in Tobruk, or via ship transport to the rest of Libya, and the surplus from local consumption is exported abroad via… Oil tankers via Hariga marina.

The monitoring consists of two coordinators:

- Operations coordinator.

- Product movement coordinator.

First: Operations Coordinator:

- Refining Department: This department has a control and monitoring room for all production and refining units of crude oil, products, and processing units.

- Warehouses Department: This department has a control and monitoring room to monitor work with 28 tanks to receive and store refinery products, a tank to receive crude oil, and a waste tank.

- Facilities Section: This section has two seawater desalination units, in addition to an oil separator and an evaporation basin.

Second: Product Movement Coordinator:

- Production Reports Section: In this section, daily, monthly, annual, and some other reports are prepared, daily notes are taken regarding production, exports, the status of the refinery, and production is followed up through the daily reports prepared by this section.

- Shipping Department: This department follows up on production in warehouses, requests the required tests for products, and prepares the necessary documents for exporting products, whether via lines or via tankers. Coordination is carried out with all relevant authorities before and after shipping operations and the approval of the required documents, as well as programming of transporters to export surplus production from the local market to the foreign market or to other Libyan cities.

Second: Monitoring the Alsirir refinery:

Resolution No. 527 of 1982 AD issued a contract with the American company Hawebaker to engineer and supply all the equipment, facilities, facilities and operating requirements required to establish a refinery with a production capacity of 10,000 barrels per day, with supervision of the installation work and initial operating trials. The implementation of the project began on 1/31/1984 AD. Implementation was completed on 3/31/1987 AD, and the refinery entered production on 1988 AD.

The refinery produces automobile gasoline 95, kerosene and diesel fuel, and the products are pumped through the pipeline to the Brega Oil Marketing Company warehouse (Sarir warehouse) and from there to various regions of Libya.

Monitoring consists of two coordinators:

- Operations coordinator.

- Product movement coordinator.

First: Operations Coordinator:

- Refining Department: It is the main unit of the refinery. This unit refines about 10,000 barrels per day of crude oil.

- Gasoline Improvement Department: This unit produces unleaded 95 automobile gasoline. 3- Facilities Section: This unit treats water and supplies the refinery units with steam (STEEM) and air.

Second, Product Movement Coordinator:

- Production Reports Section: Preparing daily production reports for the refinery, monthly and annual reports, as well as technical meeting reports.

- Warehouse and Shipping Department: It consists of a group of tanks for receiving products and a group of shipping tanks, where the products are transferred to Al-Buraiqa Company (Sarir Warehouse) and Al-Sarir field via pipeline.

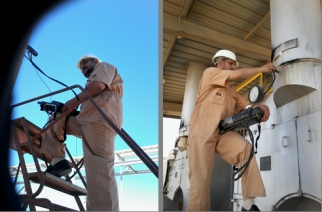

Improving the quality of operational equipment and protecting it internally and externally

Information and project follow-up coordinator

The Information and Follow-up Coordinator is one of the coordinators affiliated with the Technical Support Monitoring Department of the Technical Affairs Department and consists of the Projects Follow-up Department and the Laboratory Follow-up Department, as each department has its own different tasks.

Projects Follow-up Department

The department, in coordination with the coordinators of monitoring the implementation of maintenance projects located in the various sites of the company, follows up on the maintenance projects that were prepared by the Maintenance Engineering Supervision and contracted with contractors to implement them, as well as conducting various technical studies in the various sites of the company and evaluating the projects intended to be implemented in the near term with the rest of the projects that have A relationship with the General Administration of Operations, Maintenance, Refineries, and Technical Affairs. Among the tasks of the coordinators present in the company’s various locations is to follow up on the contractor’s technical staff, verify his academic qualifications and practical experience, approve the equipment used in the work after verifying its efficiency, provide the necessary materials for the project, and supervise the follow-up and implementation until the final delivery is completed.

Laboratory follow-up department

The department’s main tasks are to supervise, follow up, and operate all Arabian Gulf Oil Company’s field laboratories and refinery laboratories, as well as providing technical advice and linking relevant departments such as maintenance, operations, engineering, following up on the supply of equipment necessary for analysis and maintenance, conducting routine tests for crude oil and petroleum products, and issuing quality certificates. For final products according to Libyan specifications, following up on export procedures for products exported to the European market in accordance with the requirements of the European Union, conducting tests of chemical additives in coordination with technical inspection, conducting gas and water tests and tests of utility, desalination and drinking water units, as well as preparing periodic and monthly technical reports.

Process Engineering Coordinator

The Operations Engineering Coordinator is one of the coordinators of the Technical Affairs Department in monitoring technical support at the main headquarters in Benghazi and the Operations Engineering Coordinator in monitoring technical affairs in the company’s various fields and ports.

Process engineering activity: following up production operations in the fields and finding the optimal conditions for operation at the lowest costs while maintaining the safety of operators and equipment, as well as reducing environmental pollution as much as possible.

1) Oil production operations in fields

- Follow up wells that have high levels of wax and lime scales and find appropriate solutions to achieve the highest possible well productivity.

- Monitoring the anti-emulsification materials and keeping their consumption at the minimum levels that achieve the required separation rate.

- Follow up on materials that improve oil flow in the main flow lines in order to avoid high pressure in these lines.

- Follow up and evaluate the performance of surface equipment.

- Conducting physical oil balances on a daily basis to ensure the measuring meters and their conformity with actual production.

- Follow up on oil collection tanks and the validity of their safety equipment.

- Follow up on safety equipment on all equipment connected to the production line.

- Follow up on problems and interruptions that hinder the production process and find appropriate solutions for them.

- Following up on wells producing gas injection in the Nafoura field and creating a production arrangement so as to achieve the highest possible productivity with the lowest amount of gas injected.

2) Refinery operations

Process Engineering Coordination activities include the Sarir and Tobruk oil field refineries. Due to the specificity of the work of oil refineries, there are additional activities included in the work program of the Operations Engineering Coordinator to maintain the refineries’ productivity and continuity, which are: –

- Monitor and control products on a daily basis to ensure compliance with specifications.

- Monitoring production equipment, including pressure vessels, rotating equipment, heat exchangers, and tanks, to ensure they are ready at all times.

- Coordinating with the periodic maintenance coordinator, and striving to adopt the application of maintenance to the refineries using the latest methods, which allows the refineries to continue production for the longest possible operational periods while reducing the maintenance overhaul period.

- Preparing monthly and quarterly technical reports to control deviations from what was planned and fix them.

- Follow-up of projects from the Engineering and Maintenance Departments for the pre-contracting stage in order to coordinate with field operations to evaluate the suitability of work descriptions and activities to be implemented and follow up on everything related to the technical aspects of the proposed projects.

Coordinator of technical inspection and corrosion protection

The technical inspection and corrosion protection coordinator carries out and follows up on many works and activities, including protecting pipes, vessels and various equipment at all company sites with the aim of reducing corrosion rates by using chemicals and cathodic protection technology. It also conducts technical inspection (non-destructive tests) of vessels, equipment and pipes and issues the necessary recommendations for appropriate maintenance. The coordinator also conducts technical studies while trying to introduce modern technology and effective methods to reduce losses resulting from various corrosion problems to a minimum.

The technical inspection and corrosion protection coordinator consists of two departments: the corrosion protection department and the technical inspection department.

Technical inspection department:

The department carries out various technical tests for lines, vessels and equipment in accordance with the Planned Preventive Maintenance programme. The department also carries out technical inspection work and supervises maintenance work during the overhauls that are carried out periodically for laboratories and refineries, in addition to supervising the painting and welding work in the company’s oil fields and sites. .

All inspection tests are carried out in accordance with international standards and specifications (API, ASTM & ASME)

Corrosion protection section:

It consists of the internal protection unit (chemical treatment), the external protection unit (cathodic protection), and since the tasks of this department are multiple, the activity of each unit will be detailed separately.

1. Internal protection unit (chemical treatment):

The main tasks of this unit are summarized in the following points:

- Protecting equipment, vessels, and transportation lines for various products by using chemicals that work to reduce the phenomenon of corrosion. These chemicals include corrosion inhibitors of three types (water-soluble, oil-soluble, and gas-specific corrosion inhibitors), limescale inhibitors, oxygen scavengers, and hydrogen sulfide, in addition to killers. Bacteria, and this is done after conducting the necessary studies.

- The treatment efficiency is monitored by conducting the necessary chemical analyzes such as measuring the pH, measuring the percentage of the remaining substance of the chemical applied in the treatment, the percentage of dissolved oxygen, and the number of bacterial populations (SRB). Other monitoring methods include the use of corrosion rate measuring devices (Corrosion Coupons, ER probes). , LPR probes).

2. External protection unit (cathode protection):

The External Protection Unit performs many activities, including checking the voltage readings of the cathodic protection system for equipment, vessels, and main and sub-lines. It also performs maintenance operations for the equipment and devices used in the cathodic protection system (electrical transformers – solar energy transformers – tables – anode chains).